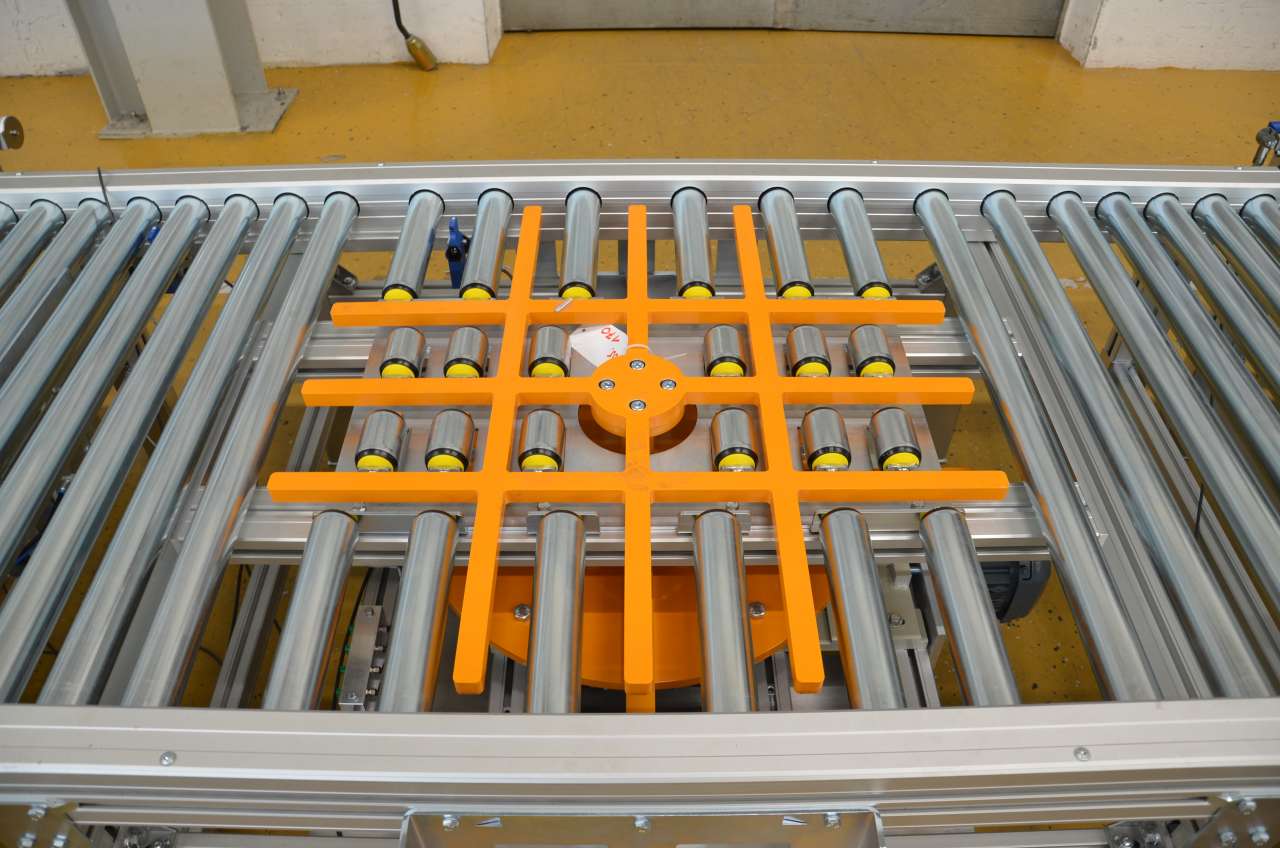

Turntables are the ideal conveyor technology for turning conveyed goods in the tightest of spaces, feeding products in and out at different angles or changing the conveying direction at any angle. They are also used as a connecting link between intersecting conveyor belts. The major advantage of using turning stations is that the orientation of the conveyed goods remains the same regardless of the change in direction

Turntables

As a competent manufacturer, TEGEL-TECHNIK offers turntables in various dimensions and shapes, depending on the intended use. The design depends on your specific requirements, operating conditions and the nature of the material to be conveyed. As with our travelling paths, stroke transfer units or vertical conveyors can various conveyor components such as roller conveyors, chain conveyors, belt conveyors, stroke transfer units or customised designs can be integrated. This makes our conveyor technology a customisable solution for your production and intralogistics. You can find a selection of our realised projects here.

Advantages of turntables from TEGEL-TECHNIK

Wide range of applications: Our turntables offer a variety of possible applications. They enable a flexible angle of rotation and allow turning in the tightest of spaces. In special applications, endlessly rotating rotary tables are also possible, which do not require a reverse rotation per cycle.

Individuality and flexibility: Thanks to the modular design of our conveyor systems, the rotary tables can be flexibly integrated into different systems.

Robust and reliable: Our components are characterised by the use of high-quality materials such as steel, stainless steel or aluminium and are carefully processed. We offer robust and durable designs with a powerful drive.

Efficiency and economy: Our turntables ensure a continuous flow of material at high speed and precision. They also facilitate the processing of conveyed goods in hard-to-reach places.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. We as a company in the field of conveyor technology draw on our valuable experience since 1982.

Design and functionality of turntables

Turntables ensure that a continuous material flow is maintained. They are always used when the conveying direction of a transported item needs to be changed, but the orientation of the transported item must remain the same. Turntables are available in a manual version, where rotation is carried out using muscle power, or as a motorised version. When turning, any angle of rotation can be realised. In order to enable safe turning, the turning stations are completely enclosed. Alternatively, they can be used in a protective grid cell.

A sub-variant of the turntable is the turnstile. This can be used to turn the conveyed goods within the transport route in order to change the orientation of the conveyed goods. This variant is often used in industry, for example on assembly lines, to enable accessibility on all sides of the conveyed goods.

Turntables in use

At TEGEL-TECHNIK, we design turntables for a wide range of applications in different sizes and shapes. They are used for example in conveyor systems to compensate for changing product flows. Turntables also enable safe working in hard-to-reach places on the workpiece, thereby increasing the productivity of the conveyor system.

We have realised several conveyor technology projects with turntables for our customers. Several turntables were installed in an assembly line for white goods in order to rotate the appliances several times. This allows the assembly steps at the front and rear to be carried out easily and efficiently. We have also realised a buffer line with a manual turntable as a workstation. An employee can turn the pallet there and remove the parts easily and safely. Another example is the transport of plastic crates. An automated guided vehicle (AGV) simultaneously delivers two plastic crates (KLTs), which must then be brought together on a track and rotated, in order to achieve the same orientation.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0