Roller conveyors are customised conveyor systems for transporting unit loads or special workpiece carriers. The goods are transported over the rollers of the conveyor and rest on at least three rollers. Roller conveyors with support rollers are used for various purposes. For example in warehouse technology, logistics and intralogistics for transporting and distributing unit loads, as well as in production lines or for feeding workpieces into robot cells and machining centres. In addition, roller conveyors can connect different warehouses and logistics halls with each other. For this type of conveyor technology, the goods to be transported must be suitable for roller conveyors and have a smooth or level floor. It doesn't matter whether the floor is level, slightly sloping or on different levels - our systems can handle any curve, length and height, even with heavy goods!

Roller conveyors

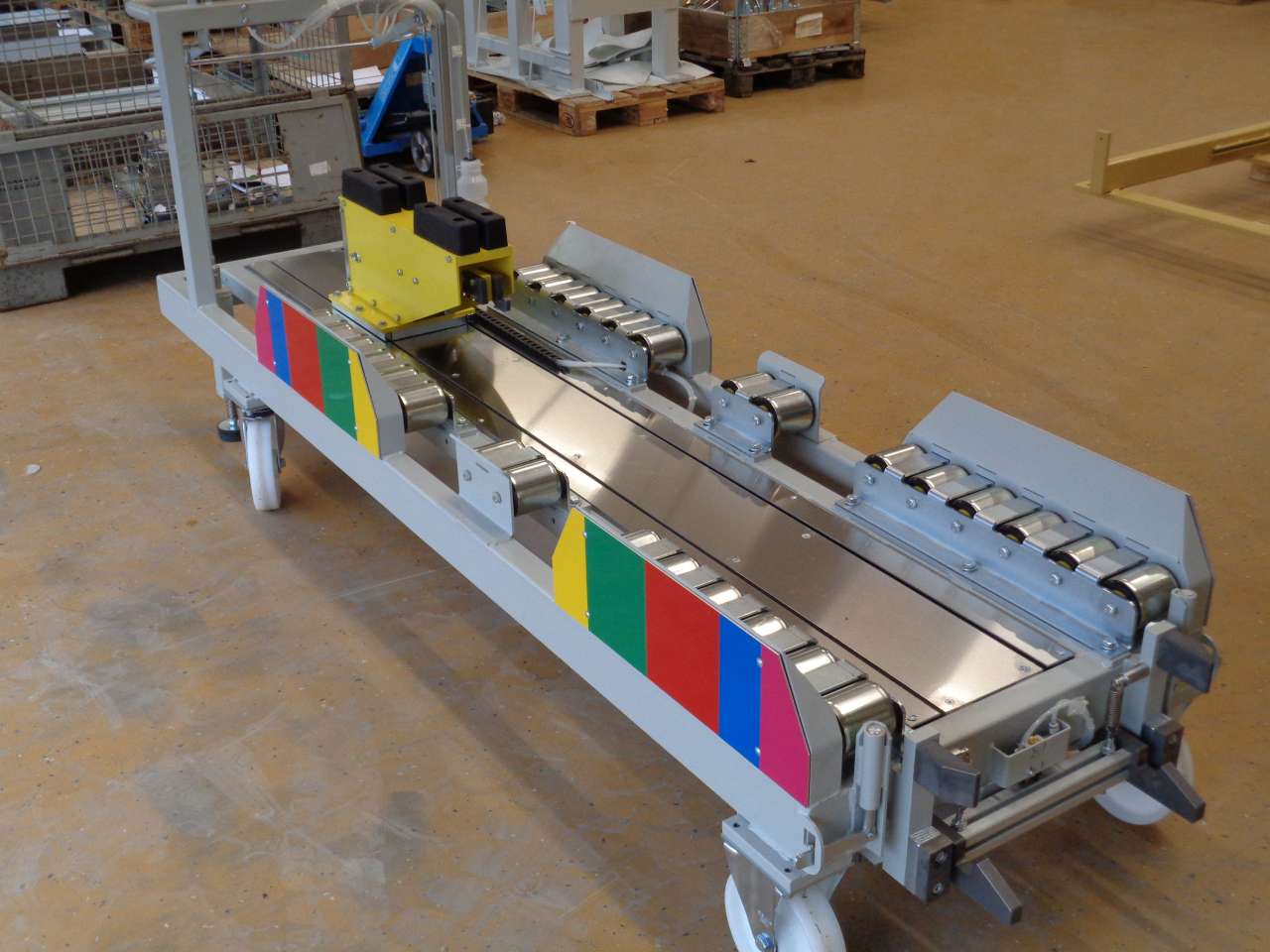

TEGEL-TECHNIK offers a wide variety of roller conveyors for a multitude of applications. These include Lroller conveyors, driven roller conveyors with geared motor, roller conveyors with motorised roller for low loads or zero pressure accumulation transport, accumulation roller conveyors and roller curves. You can find a selection of our realised projects here.

Advantages of roller conveyors from TEGEL-TECHNIK

Broad range of applications: The areas of application for our roller conveyors include the transport of light goods weighing just a few grams, pallet conveyor technology and the transport of special goods weighing several tonnes.

Individuality and flexibility: We develop and build conveyor systems according to your specific needs and spatial conditions. Our roller conveyors are individually configured and can therefore be flexibly connected to your existing systems.

Rugged and reliable: Our components are characterised by high-quality materials and meticulous workmanship. We supply robust and durable designs that are suitable for conveying in a wide range of conditions.

Efficiency and economy: By automating transport tasks, our roller conveyors help you to increase the efficiency of your processes in operation.

Everything from a single source: we offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Structure and functionality of roller conveyors

The basis of roller conveyors is a frame. Light roller conveyors for light goods are made of aluminium profiles. Heavy-duty roller conveyors for heavy goods on the other hand are made of painted steel elements. We use our own TT aluminium profile system for this. Rotating idlers are arranged in parallel one behind the other in the frame structure. Depending on the application, the roller conveyor is equipped with a drive. The drive elements of the steel rollers are located in a protective housing. This protects both the drive elements from soiling and the operator from injury. Power is transmitted from the drive to the individual steel rollers via chains or belts. Idle roller conveyors do not have an electric drive and are driven by gravity or muscle power .

Changes in direction can be implemented on roller conveyors using various components. With roller curves and turntables, the direction of the conveyor section changes while the orientation of the conveyed goods remains the same, whereas lift converters change the orientation of the conveyed goods.

Roller conveyors in use

At TEGEL-TECHNIK, we realise roller conveyors for numerous areas of application and a wide range of industries. Thanks to our wide range and web width we find the optimum solution for every application and design the conveyor system individually for you.

We have realised various projects with roller conveyors for our customers. In the despatch area, our roller conveyors convey various box sizes. We mainly use our TT aluminium profile system as the basis for this. In internal transport logistics, our roller conveyors transport Euro or special pallets and are mounted on a frame made of robust steel elements. The production line area, on the other hand, often places special demands on the conveyor technology. Here, the conveyed goods often need to be rotated, swivelled or lifted to different heights. We work closely with our customers to develop a customised solution. The centre distance, track width, overall width and roller diameter are just some of the factors that need to be taken into account. We also discuss possible accessories, such as a side guide that is suitable for use with specific transport goods, during the planning stage.

The handling of heavy loads can also be realised with our conveyor technology. We have implemented a customised workstation for our customer. The width-adjustable and swivelling idle roller conveyor enables ergonomic, efficient and easy work on steel workpieces of various sizes

Roller conveyors are also used to transport loads and goods between the production area and different zones in the warehouse. Thanks to the modular design of roller conveyors, the various conveyor sections can be easily and flexibly linked - even over a curve.

Roller conveyor designs from TEGEL-TECHNIK

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0