Belt conveyors belong to the category of continuous conveyors and transport goods from A to B fully automatically. The conveyed goods are transported via belts, from which the name belt conveyor or often also belt conveyor is derived. This type of conveyor system is used for the continuous or synchronised transport of a mass flow between different stations. They are particularly suitable for transporting very small goods such as piece goods or bulk goods as they have a full-surface transport support.

Belt conveyor

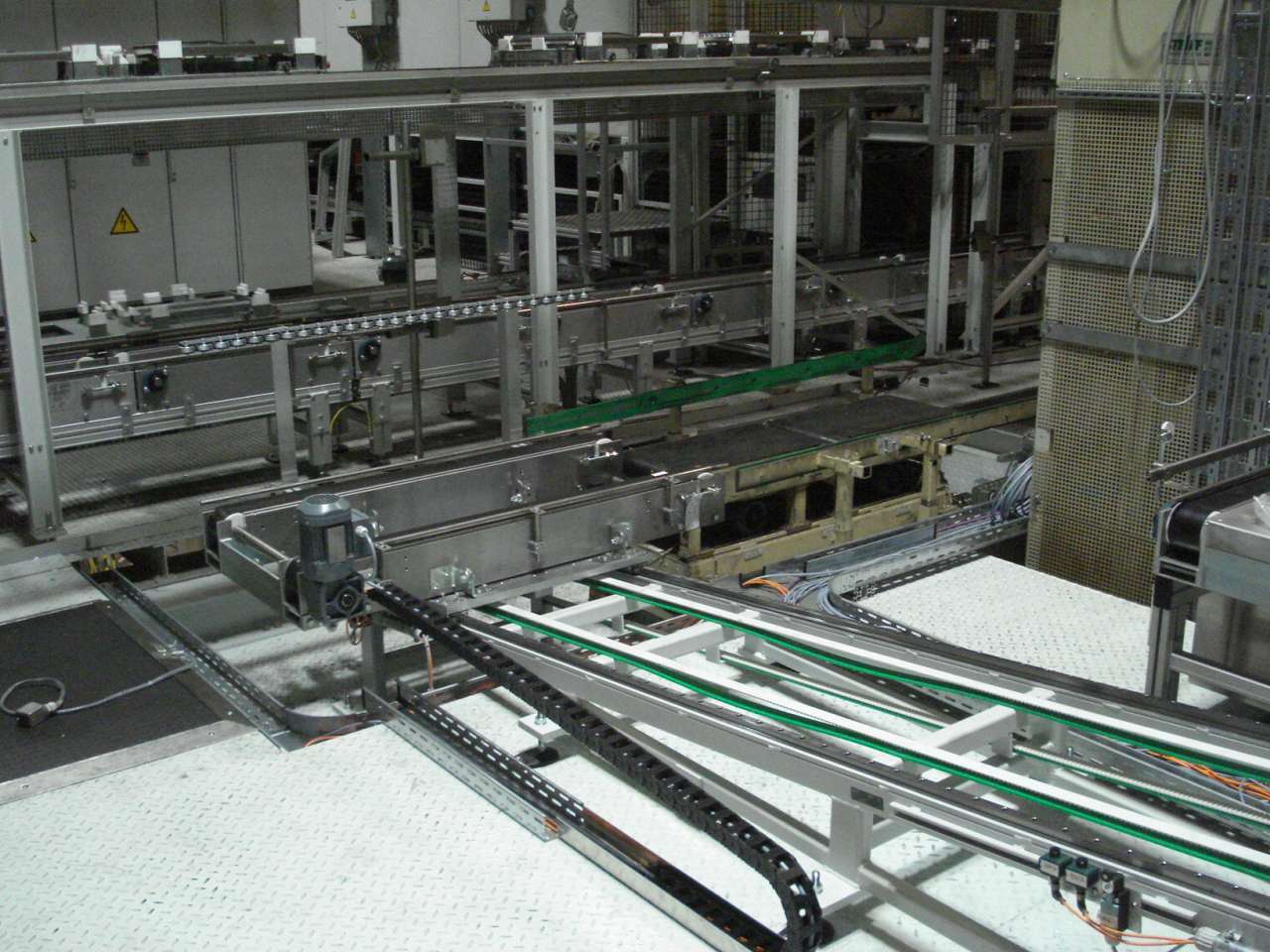

As a competent manufacturer TEGEL-TECHNIK offers a wide range of conveyor systems, because individual applications and special transport goods require a customised solution. Rubberised fabric belts are particularly common in belt conveyors. These can also be found in the family of chain conveyors e.g. with modular belt conveyors, apron conveyors or slat-band chain conveyors. You can find a selection of our realised projects here.

Advantages of belt conveyors from TEGEL-TECHNIK

Broad range of applications: Our belt conveyors are suitable for complex transport tasks, as they cover large lengths and quantities as well as different speeds of the goods to be transported.

Individuality and flexibility: We adapt the belt conveyors flexibly to your needs and circumstances. Whether space is limited or there are inclines and declines within the conveyor line, we design the optimum solution for you. Mobile belt conveyors are also part of our repertoire.

Robust and reliable: Our components are characterised by high-quality materials and careful workmanship. We supply robust and durable designs with a powerful drive.

Efficiency and economy: Our belt conveyors are low-maintenance and low-wear and guarantee fast, gentle and quiet transport in your business.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we draw on our valuable experience since 1982.

Structure and functionality of belt conveyors

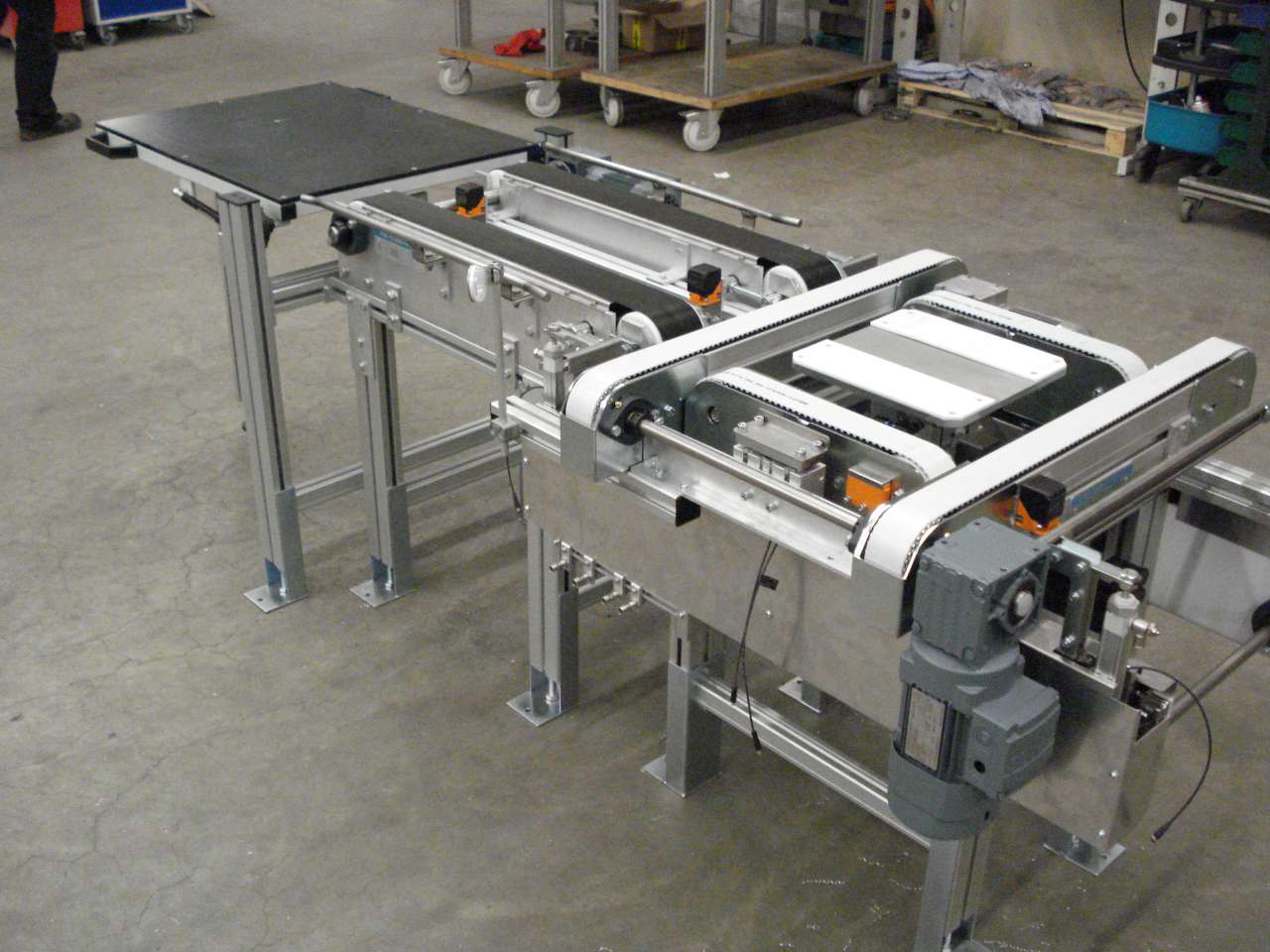

Belt conveyors essentially consist of a supporting structure, a drive and deflection station and the conveyor belt. The design varies, depending on the goods being conveyed, in single or double belt conveyors. Due to the simple design of conveyor belts, they are very robust and low-maintenance. The conveyor belt is driven by a direct drive as a head or centre drive with attachment to the side of the conveyor belt. If space is limited, the drive can also be positioned under the conveyor belt and connected to the drive drum via a roller chain. Belt conveyors can also be used to overcome inclines and gradients within the conveyor section.

The choice of conveyor belt depends on the specific application and the nature of the transported goods. Conveyor belts with a smooth surface are used, for example, for horizontal transport, while belts with a textured surface, side guides or with flights are used for inclines. Abrasion-resistant belts are particularly useful for sharp-edged parts in industry .

Belt conveyors in use

At TEGEL-TECHNIK, we design conveyor technology for different industries and applications. We find the right solution for your needs, from planning to installation. Belt conveyors are the preferred choice for overcoming inclines, gradients and curves. They enable fast, gentle and quiet transport and removal.

Conveyors with conveyor belts transport goods with different weights, dimensions, shapes or uneven contact surfaces. Our customers' applications include conveying cardboard boxes, dishwasher baskets, small electrical machines, foam sheets, plastic parts, injection-moulded plastic parts, punched sheet metal parts, waste, polystyrene bases and blocks or small parts. Depending on the requirements of the goods to be conveyed, various profiles can be applied to the conveyor belts, for example gentle rubber cleats, cross cleats or corrugated edges, to make the system as efficient as possible.

Among other things, we have used a belt conveyor as an ascending belt for our customers to enable the transport of plastic crates to a higher level. For sharp-edged, hot or wear-critical goods, however, we use hinged belt conveyors made of steel, as they are particularly robust and hard-wearing.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0