Chain conveyors are internal conveyor systems for transporting unit loads. Conveyance takes place via one or more circulating chain strands on which the goods to be transported lie. Conveyor technology with chains belongs to the category of continuous conveyors and is characterised by almost limitless application possibilities. It is often used for the transport of conveyed goods with small contact surfaces. Even hot, oily, sharp-edged and very long conveyed goods can be transported safely and reliably with these conveyors.

Chain conveyor

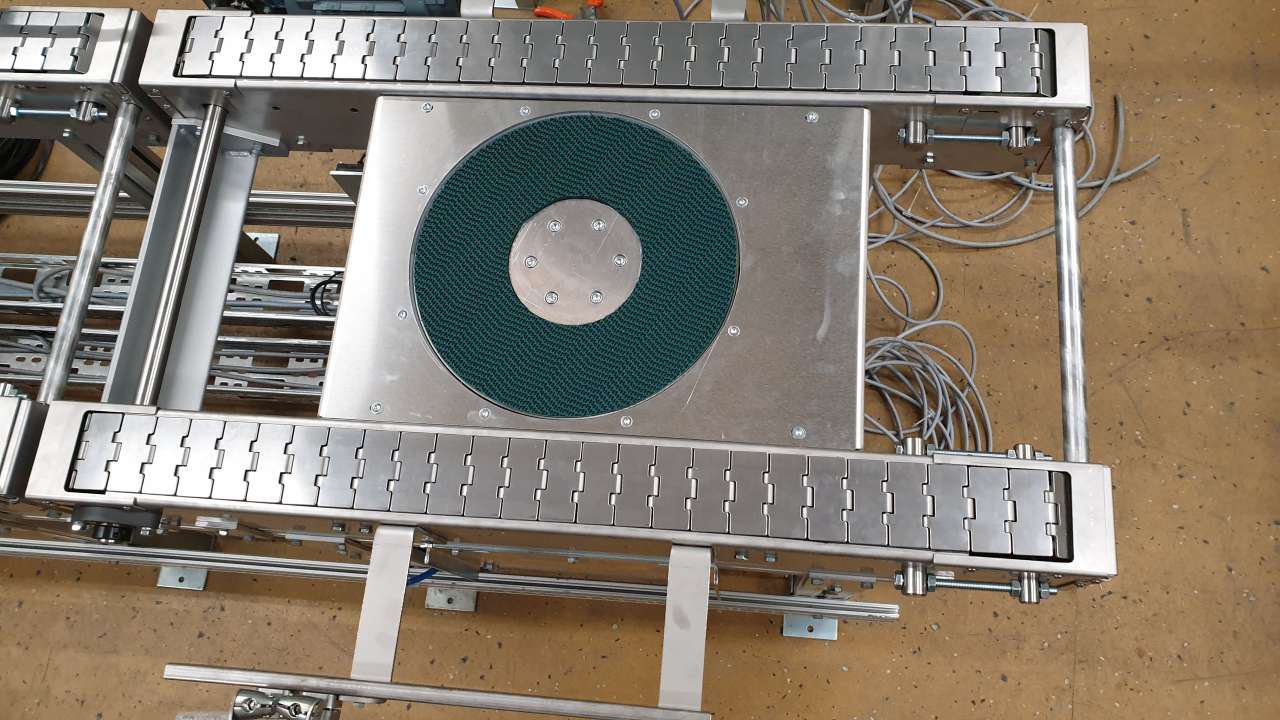

TEGEL-TECHNIK offers a wide range of chain conveyor variations for different applications, e.g. carrying chain conveyors, modular belt conveyors, apron conveyors, hinged belt chain conveyors and accumulating roller chain conveyors. You can find a selection of our realised projects here.

Advantages of chain conveyors from TEGEL-TECHNIK

Broad range of applications: Hot, oily, sharp-edged or extra-long goods - with our chain conveyor system you can transport almost any conveyed goods.

Individuality and flexibility: We offer chain conveyors in different designs, tailored to the nature of your conveyed goods. Thanks to our modular design, the components can also be flexibly integrated into your existing system.

Robust and reliable: Our chain conveyors are characterised by a robust design with high resistance to external influences and a powerful drive .This enables even heavy loads to be transported.

Efficiency and economy:Our chain conveyors are durable and low-maintenance conveyor elements. They enable cost-effective transport of your conveyed goods.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we draw on our valuable experience since 1982.

Design and functionality of chain conveyors

Based on a robust steel or aluminium base profile, chain conveyors use one or more circulating chain strands. Multi-track systems are mainly used for unit loads of different sizes to ensure support for all dimensions.

The drive sprockets are connected to each other via a shaft and are driven by an electric motor. Depending on the conveyor design, with roller chain, modular belt or slat-band chain, the conveyor system is suitable for different types of goods. The dimensions, shape and weight, as well as the temperature and the surface on which the goods are placed are decisive factors here. Special workpiece holders can also be fitted to chain conveyors.

Depending on the purpose of the conveyor system, different variants of chain conveyors offer different advantages. Very wide conveyor sections can for example be realised via carrying chain conveyors , while on accumulating roller chain conveyor the transported goods can be accumulated. Inclines, e.g. for discharging punching waste, for example, can be accumulated by hinged belt chain conveyors or Modular belt conveyors can be overcome. For the transport or production of pallets, we recommend our conveyor technology, which has been specially adapted for pallets.

Chain conveyors in use

At TEGEL-TECHNIK, we design conveyor technology for various industries and applications. Compared to roller conveyors, chain conveyors can also transport containers and transport devices that have a very small footprint. Goods with feet that are unsuitable for roller conveyors can also be transported using chain conveyors. Transport by a continuous and guided chain is also safe and reliable for such goods. Even very long conveying distances can be realised with this conveyor system.

We plan your conveyor technology individually and select the conveyors to suit your specific requirements and framework conditions. We combine different components and develop the optimum solution for you. Our projects are just as diverse as the industries and applications of our customers. Among other things, we have designed a system for the feeding of large load carriers weighing up to 500 kg into a robot station. This involved carrying chain conveyors and stroke transfer conveyors in combination with driven roller conveyors for use.

In another project, we realised the transport of crash barriers with a package weight of up to 5.5 t and a length of 4.3 m. The conveyor line consisting of carrying chain conveyors and scissor lift tables is used to transport crash barriers in packages and to remove residual water by lowering scissor lift tables.

Chain conveyor designs from TEGEL-TECHNIK

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0