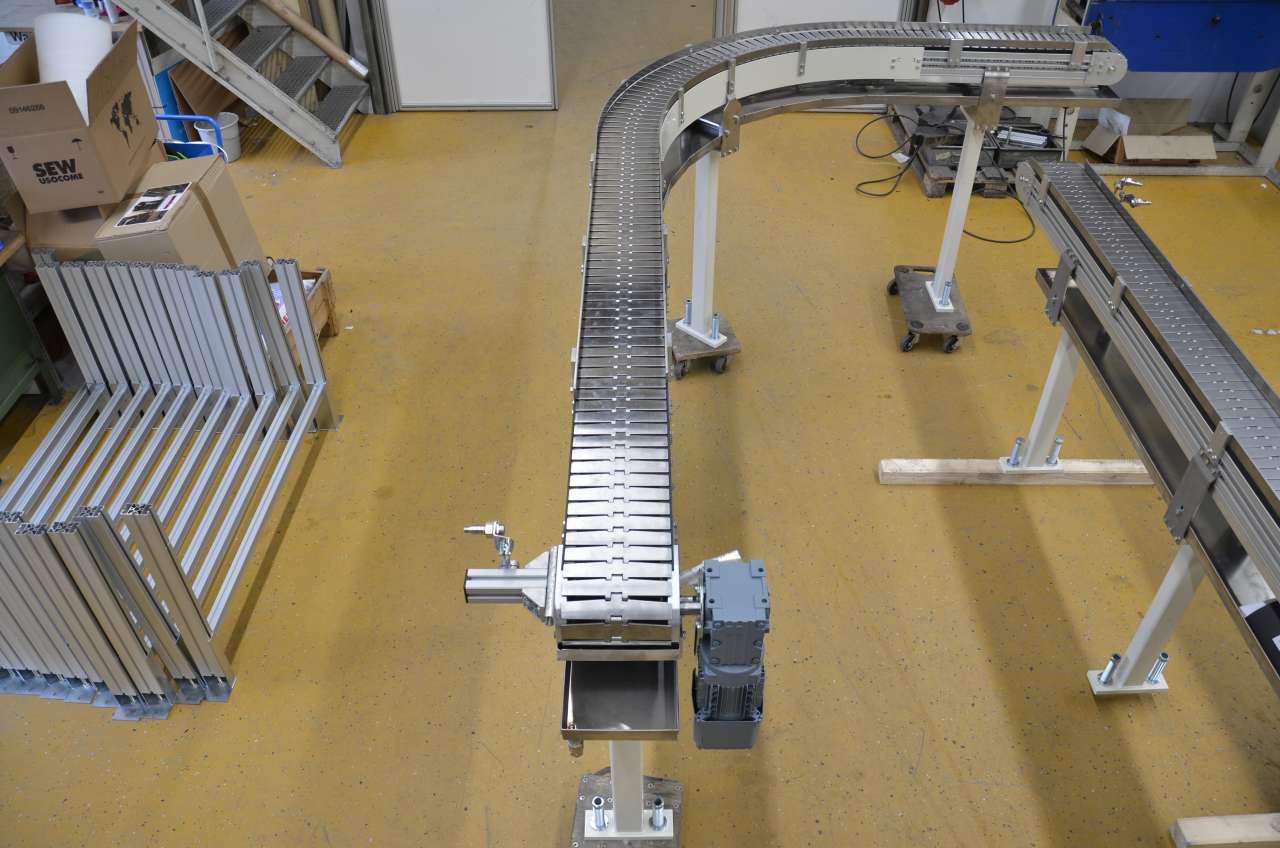

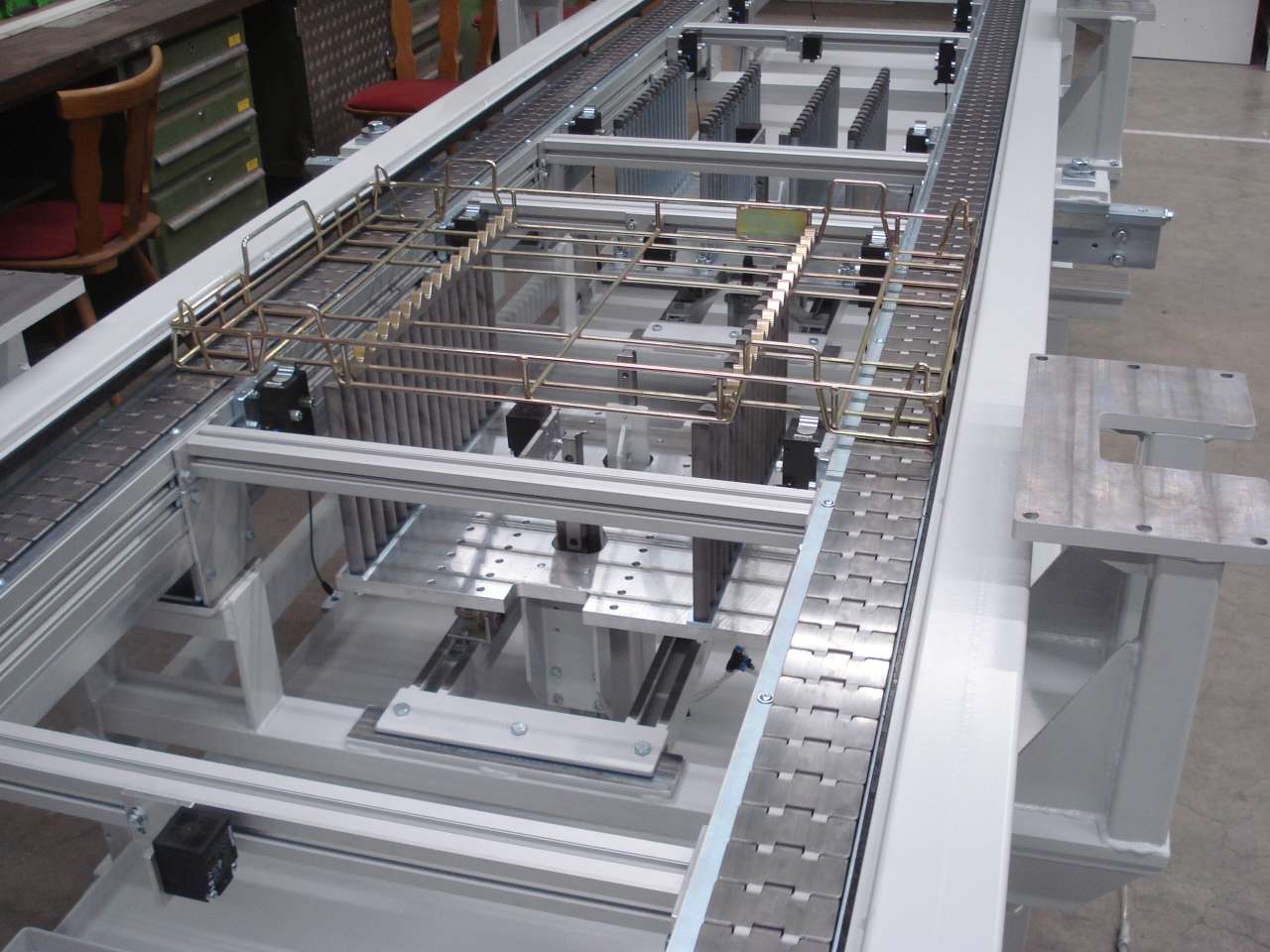

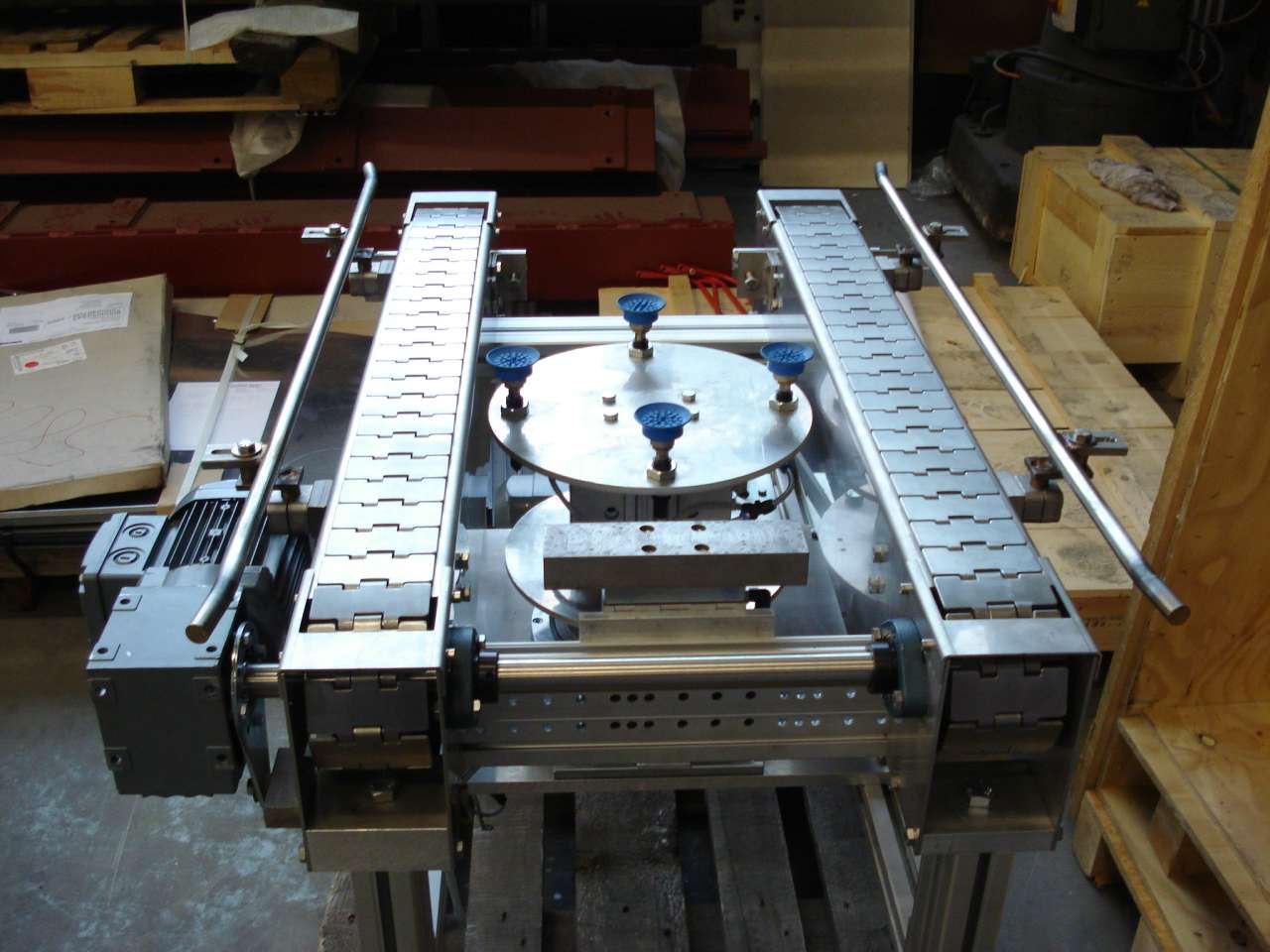

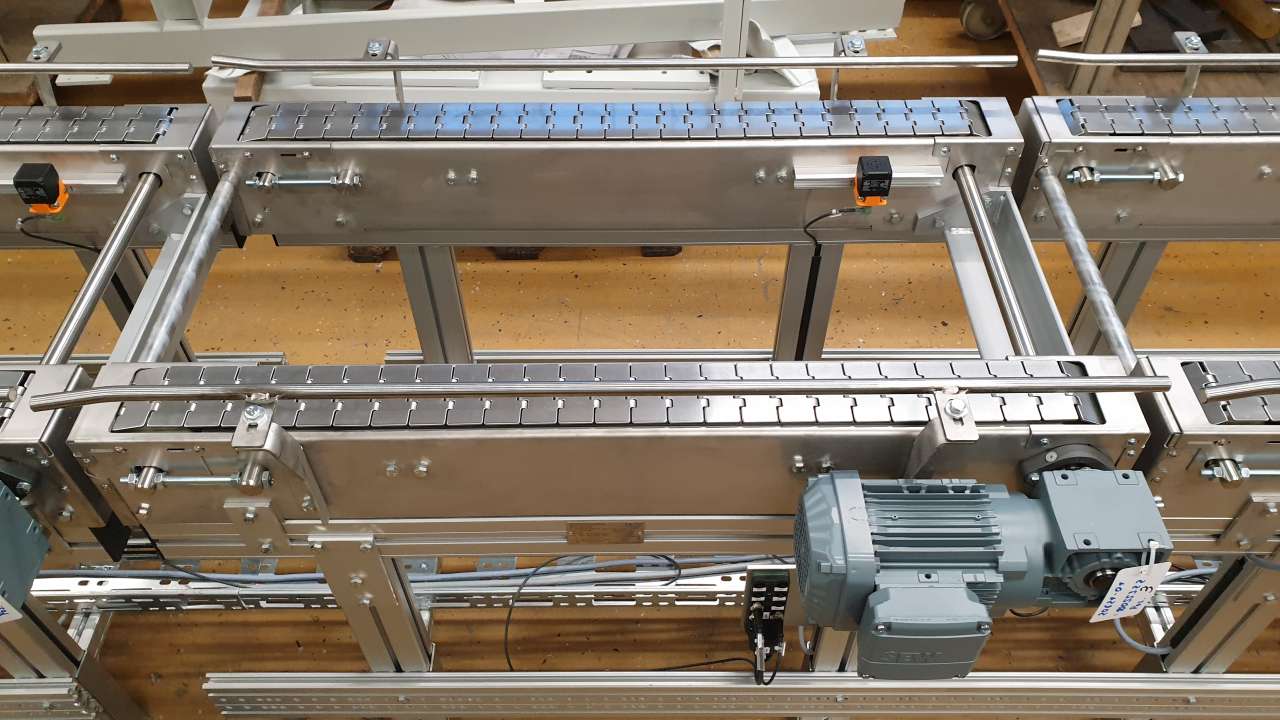

Hinged belt chain conveyors are used in a wide range of applications in various industries, especially for transporting unit loads. Their great advantage lies in the variety of designs, the modular structure and the ease of cleaning. The slat-band chain conveyor consists of individual interconnected steel or plastic elements. This makes them robust, low-maintenance and easy to clean. The individual plastic elements can be easily replaced in the event of maintenance or repairs and enable inclines or declines to be overcome. Hinged belt chain conveyors are available with steel or plastic hinges. They enable transport on straight and winding routes and are characterised by space savings and the possibility of transport on several levels.

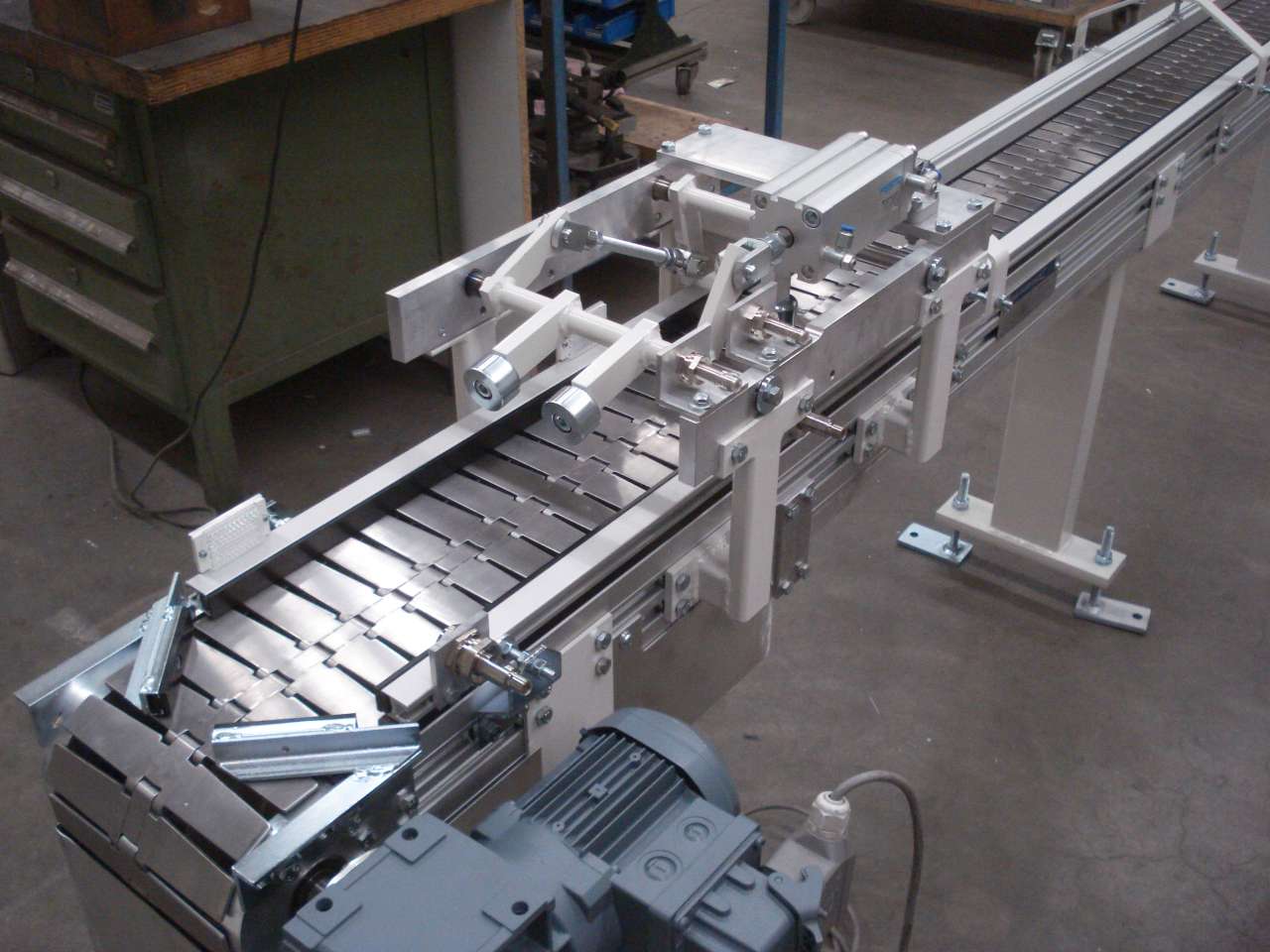

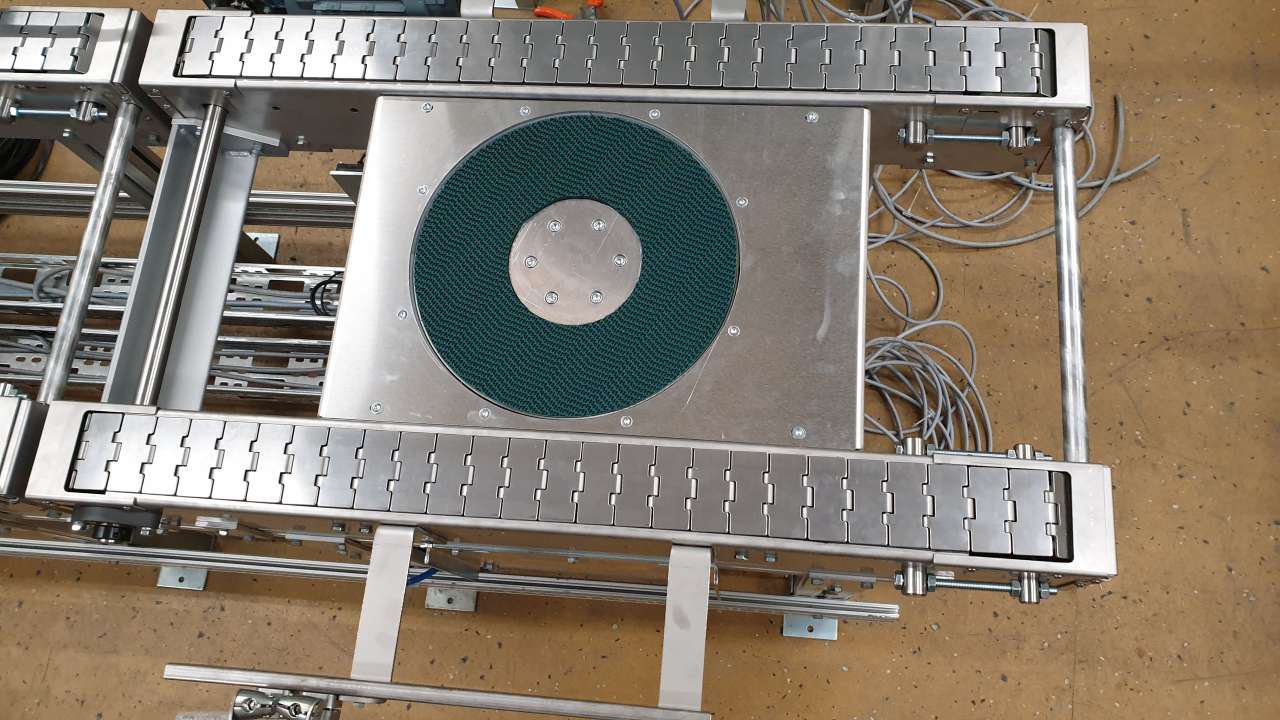

Slat-band chain conveyor

Steel slat-band conveyors are characterised by their robustness and durability. They are particularly suitable for transporting sharp-edged, hot or wear-critical goods such as Euro pallets, mesh boxes, cans, saw cuts, punched parts, connecting rods, brake discs, hubs, cotton buds, plastic containers, sharp-edged sheet metal, crates or bottles.

The form-fit drive of hinges, sprockets and chain enables slip-free, constant and correct chain guidance. In addition, tensioning systems are not necessary. There are many hinge variants that can be selected depending on the conveyed goods and application. Depending on the application, the hinged belt conveyor can be equipped with a smooth, perforated, slotted or dimpled surface, for example.

Transport can be either continuous or intermittent. Hinged belt chain conveyors can also be used in reversing mode. Multiple strands are usually driven via a drive shaft. For heavy loads, the hinged chain conveyors are either equipped with their own geared motor or are driven by shaft couplings.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0