Vertical conveyors are used in production and internal logistics to transport product flows vertically, i.e. upwards or downwards. In doing so, they distribute the goods to be conveyed over several levels and thus overcome specified height differences within a conveyor section in the tightest of spaces. Depending on the nature of the transported goods, our vertical conveyor systems are equipped with the appropriate conveyor technology in order to design the optimum solution for every application.

Vertical conveyor

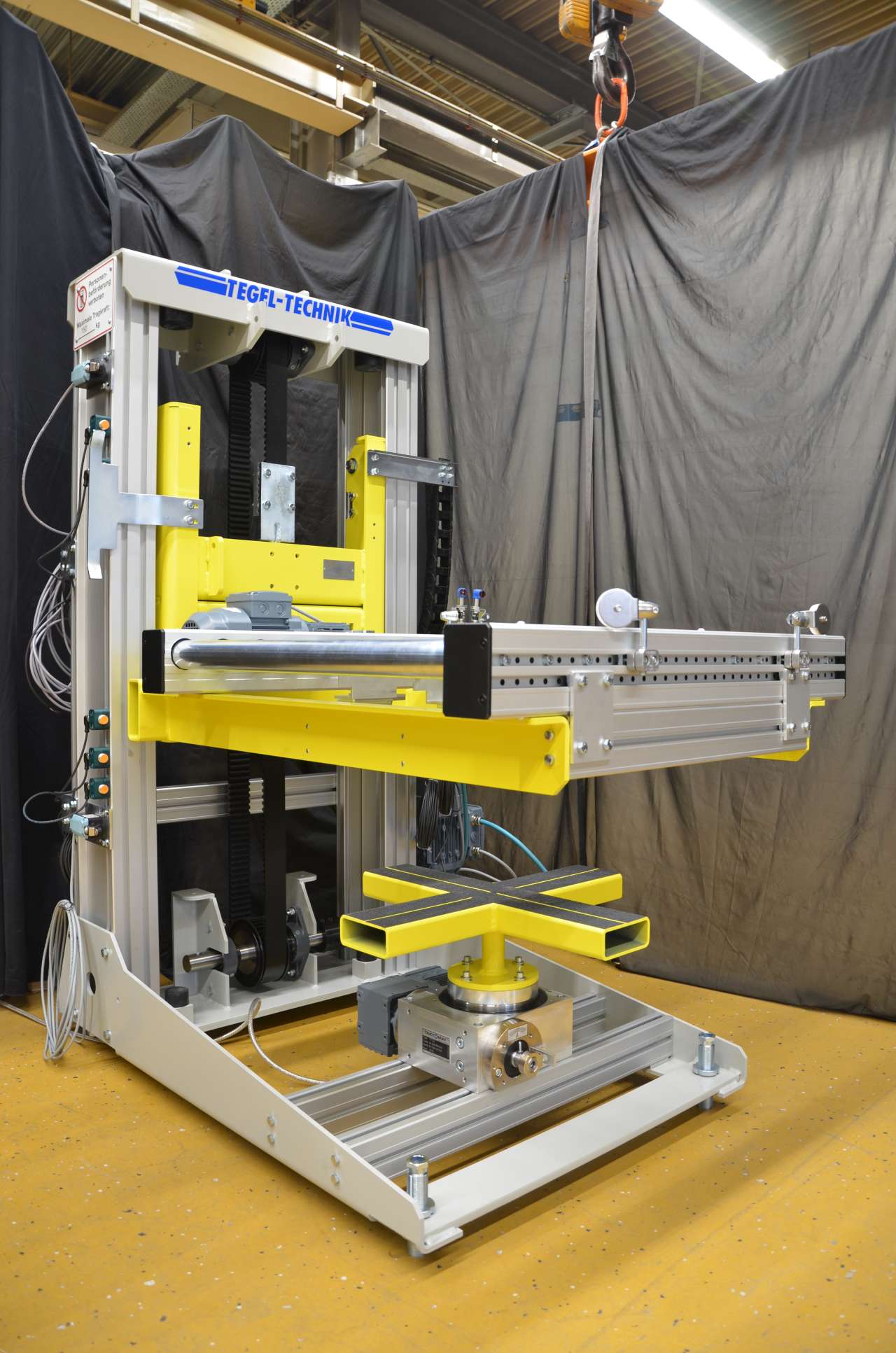

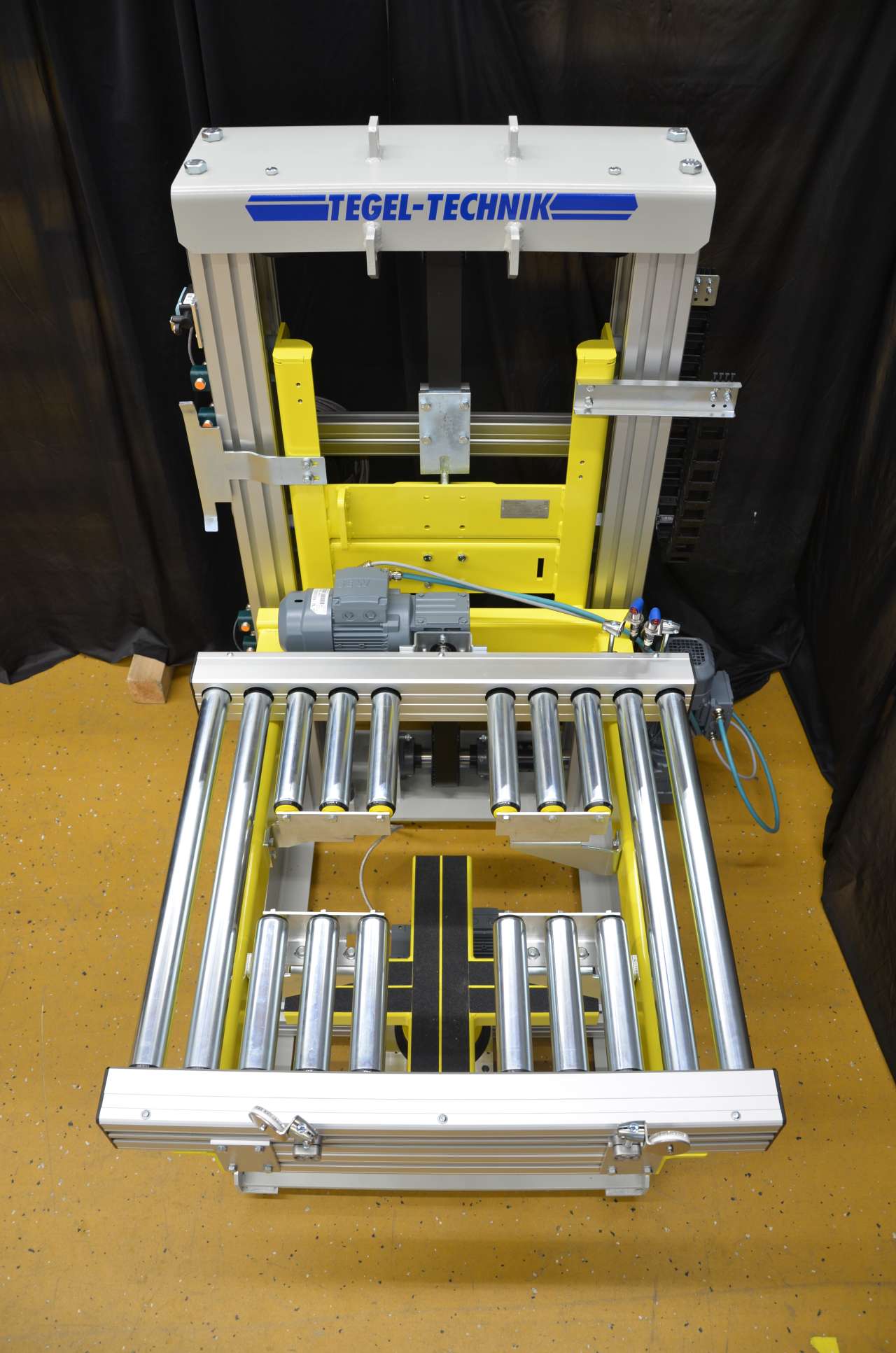

Vertical conveyors are often also referred to as vertical conveyors and, like our rotary tables and travelling carriages with different conveyor components such as roller conveyors, chain conveyors, belt conveyors, belt conveyors, telescopic forks or special designs. This makes them a universally applicable conveyor technology for our customers' production and intralogistics. You can find a selection of our realised projects here.

Vorteile der Vertikalförderer von TEGEL-TECHNIK

Broad range of applications: We design vertical conveyors in various versions and designs. This allows us to connect to almost any conveyor system for transport to different levels.

Individuality and flexibility: We work with a modular system in which the vertical conveyors can be flexibly equipped with different conveyor components. This gives you a solution that is specifically tailored to your vertical transport requirements.

Rugged and reliable: Our components are characterised by high-quality materials and meticulous workmanship. We supply robust and durable designs with powerful drives.

Efficiency and economy: Our vertical conveyors allow you to make the best possible use of the available space while optimising the material flow in operation. They transport goods to other floors or to an ergonomic working height, making work easier for your employees.

Everything from a single source: We offer a high level of vertical integration with an extensive range of products and services. We have been drawing on our experience since 1982.

Design and functionality of vertical conveyors

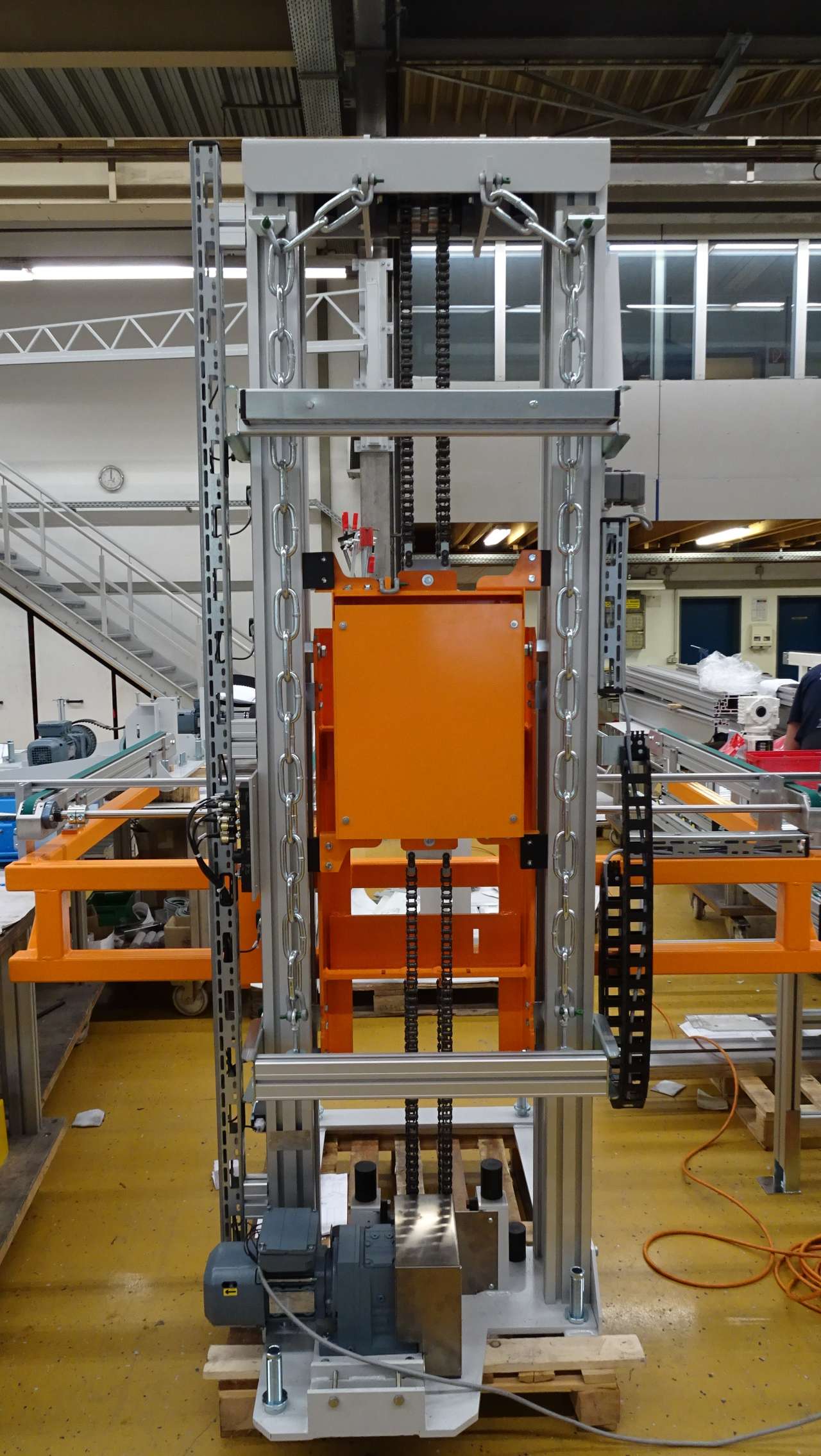

The basic structure of vertical conveyors is a stable profile construction made of steel or aluminium, whereby the static and dynamic requirements determine the design type of the machine. They can be equipped with different control and regulation technology. The automated goods lift can be flexibly integrated into almost all existing conveyor and production systems.

Vertical systems are available in various versions and designs, such as lift tables with a high adjustment frequency, floor lifts or elevators. Elevators have the advantage of being able to transport several conveyed goods at the same time (paternoster principle). They are available with aluminium or steel columns as single-column, two-column or four-column versions.

Vertical conveyors in use

At TEGEL-TECHNIK, we specialise in the design of customer-specific conveyor lines and offer conveyor systems tailored to your individual requirements. A particular advantage of using vertical conveyors is that conveyor lines can be constructed in three dimensions rather than just two. This means that the height of a room can also be utilised and floor space can be saved.

Vertical conveyors make it possible to split a conveyor section into different connecting sections at different levels, as well as to return empty containers or goods carriers to the start of the conveyor section at a different level. The vertical movement of the systems can also be used to move to different heights for the ergonomic design of workstations and assembly processes.

We have realised a large number of projects with vertical conveyors for our customers. Among other things, we have designed a conveyor line for the inspection and evacuation of refrigeration appliances constructed. Vertical conveyors are used to lower the appliances to an ergonomically appropriate level for the final inspection. Another example of the use of a vertical conveyor is the separation of stacked pallet cages. In this application, the vertical conveyors were not equipped with the usual conveyor elements such as roller conveyors or chain conveyors, but with fork tines. The vertical conveyor is part of a conveyor technology for pallet cages in a robot cell.

Gallery of application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0