We are your specialist for complete systems and individual components in the field of conveyor technology. With our customised solutions for a wide range of industries, we have been promoting the success of our customers since 1982. Each industry has its own special requirements for the planning, production and assembly of conveyor technology. For us, this means creating systems with maximum flexibility. We are happy to take on this task, because we make your requirements our challenge. From assembly and automation to material flow and handling with the corresponding control and drive technology - with us you receive the complete conveyor technology from a single source. As a manufacturer of conveyor systems, we always pursue the goal of finding the most economical and efficient way for your project.

Complete systems

When realising your projects, we rely on

Flexibility and individuality: Thanks to our modular system, there are (almost) no limits to conveyor system construction. This allows us to develop and implement solutions for your individual requirements. Your needs are our focus.

Experience and reliability: Founded in 1982, we have over 40 years of experience in the implementation of individual automation and rationalisation projects. As a family business, all our decisions are made responsibly and sustainably.

Comprehensive complete solutions: From conveyor belts and roller conveyors to chain conveyors - we customise every conveyor technology to your individual requirements and framework conditions. We also realise special solutions according to your ideas.

Everything from a single source: We offer a comprehensive range of services as well as a high level of vertical integration in every type of plant engineering.

Conveyor systems with a modular system

We use a modular system for sophisticated conveyor systems. This means that various designs and materials are available for our conveyor technology. We utilise the diverse design options of our development to find and implement the optimum solution for your specific framework conditions. Depending on the requirements of your conveyed goods and the environmental influences, we manufacture our conveyor systems either from steel, stainless steel or our in-house TT aluminium profile system. A combination of materials is also possible.

Our modular design offers you maximum flexibility and individuality. Construction, mechanics, electrics, hardware and software - all components are designed and combined exactly as your project requires.

Customised designs for conveyor systems according to your requirements

We adapt our conveyor technology to your individual conveyed goods, location factors and production processes in order to realise the optimum result for you. We also realise special designs such as special machines, workpiece carriers, handling devices or devices for you. We find the ideal conveyor technology for every automation system and offer customised complete solutions, even for demanding requirements.

If required, we can also equip our components with additional elements such as scales, contour checks or control devices, e.g. workpiece checks or position checks. We make your requirements our challenge.

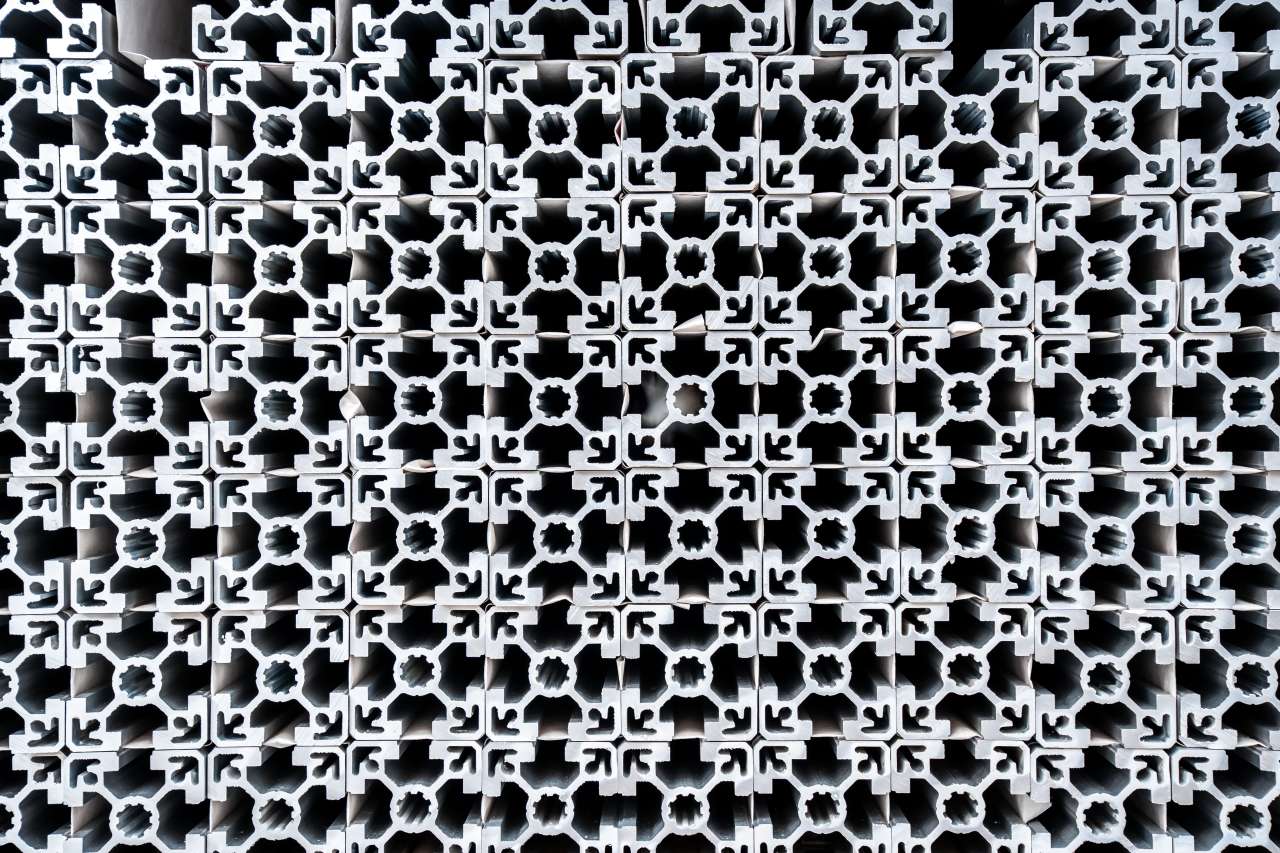

TT aluminium profile system

Our anodised TT aluminium profile systems guarantee stable and flexible components. In addition, the units are easy to shorten or lengthen and can be extended at any time. All components are matched to each other and can be used in modular form thanks to our modular system.

The longitudinal grooves in our anodised TT aluminium profile systems mean that attachments such as supports, side guides or sensors can be retrofitted at any time.

This enables us to

Feed, distribute, buffer, weigh, sort, pick, stack and unstack the conveyed goods.

Lift, lower or rotate the conveyed goods.

Optimise cycle times.

Load and unload machines and stations.

Interlink or decouple production equipment.

Design assembly and testing stations according to ergonomic aspects.

Minimise downtimes with maintenance-friendly designs.

Visualise the system, integrate it into existing production and intralogistics and network it with them.

and much more ...

Improve transport and operation with components

In addition to complete systems, we also offer a comprehensive selection of components for expanding or optimising your conveyor system. Through specific customisation, our components can be integrated into your existing conveyor technology or combined to form a new complete system.

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0