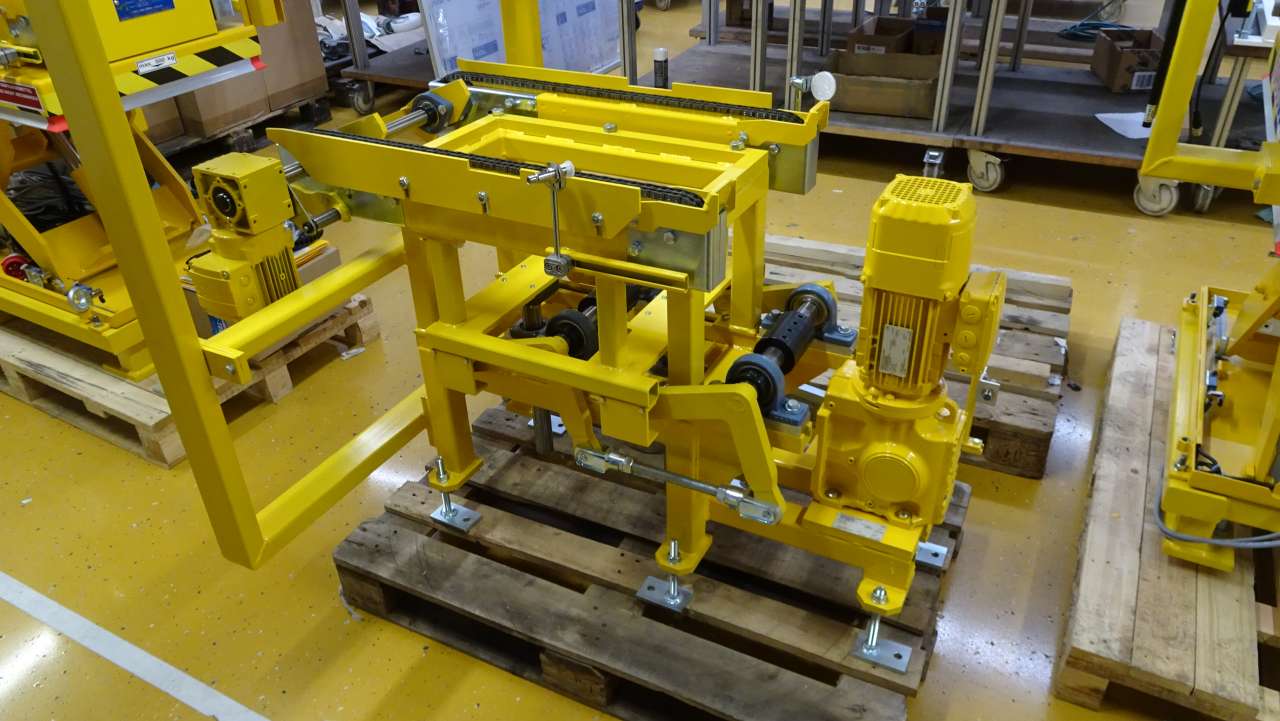

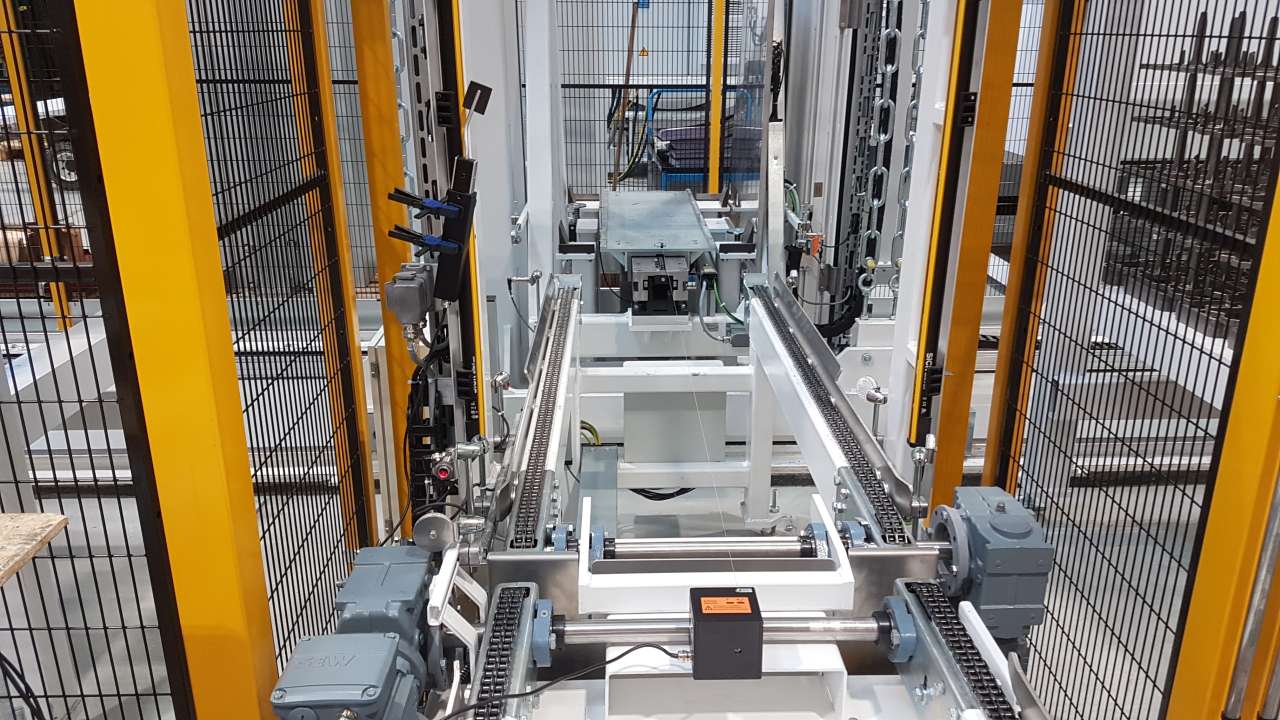

Carrier chain conveyors are conveyor systems that are used for handling and transporting goods, components or materials in various industrial applications. They consist of two- or multi-strand frame elements in which a roller chain is guided around the circumference. During transport, the conveyed goods rest on the chain. The chain assumes a load-bearing function, from which the name of the conveyor is derived. The chains move continuously on rails or guide elements, moving the transported goods over a defined distance. Carrier chain conveyors are characterised by the small contact surface required for the transported goods. This makes them suitable for transporting a wide variety of goods, such as mesh boxes, pallets, workpiece carriers, special load carriers, steel profiles, load carriers for exhaust systems, roller containers, hardening frames, cast parts, steel boxes, crash barriers and much more.

Carrier chain conveyor

In addition to carrier chain conveyors, we offer different variants of chain conveyors. These include modular belt conveyors, panel belt conveyors, Hinged belt chain conveyorsand accumulating roller chain conveyors. You can find a selection of our realised projects here.

Advantages of chain conveyors from TEGEL-TECHNIK

Broad range of applications: Our chain conveyors are extremely versatile, as the chain size can be customised to suit your transported goods and the respective application. As a result, our chain conveyors are used in a wide range of industries, particularly in logistics.

Individuality and flexibility: The design of our flexible chain conveyors varies depending on the type of goods being conveyed. Two-strand or multi-strand chain conveyors with chain sizes adapted to the transported goods can be used.

Rugged and reliable: Our chain conveyors are characterised by a high payload and stable design. As a result, the conveyors also prove themselves in demanding environments. Our solutions are particularly suitable for conveying unit loads or parts with a high weight, for example in processing or assembly.

Efficiency and economy: Our chain conveyors help to make your material transport in production processes more efficient and smoother.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Design and functionality of chain conveyors

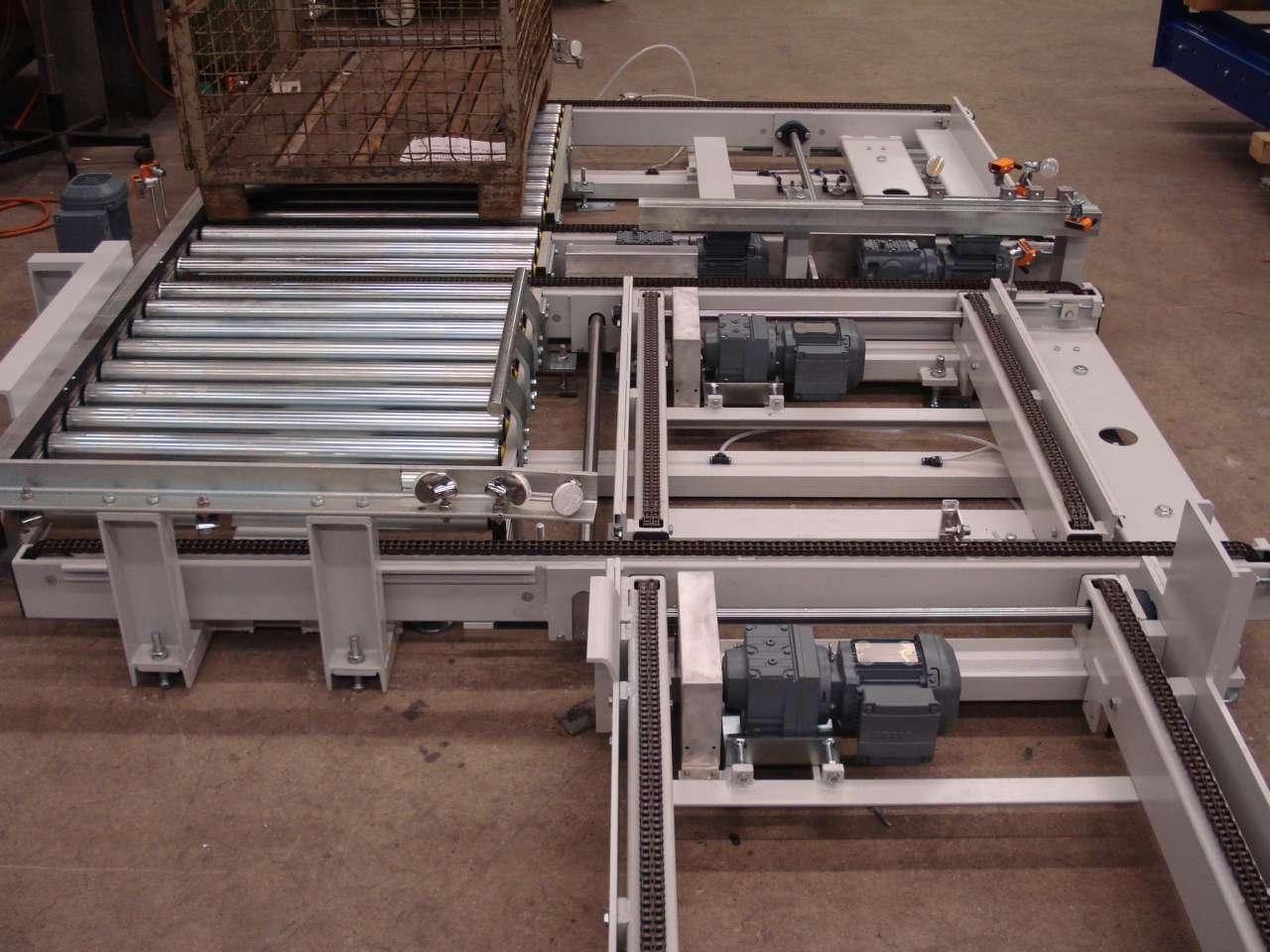

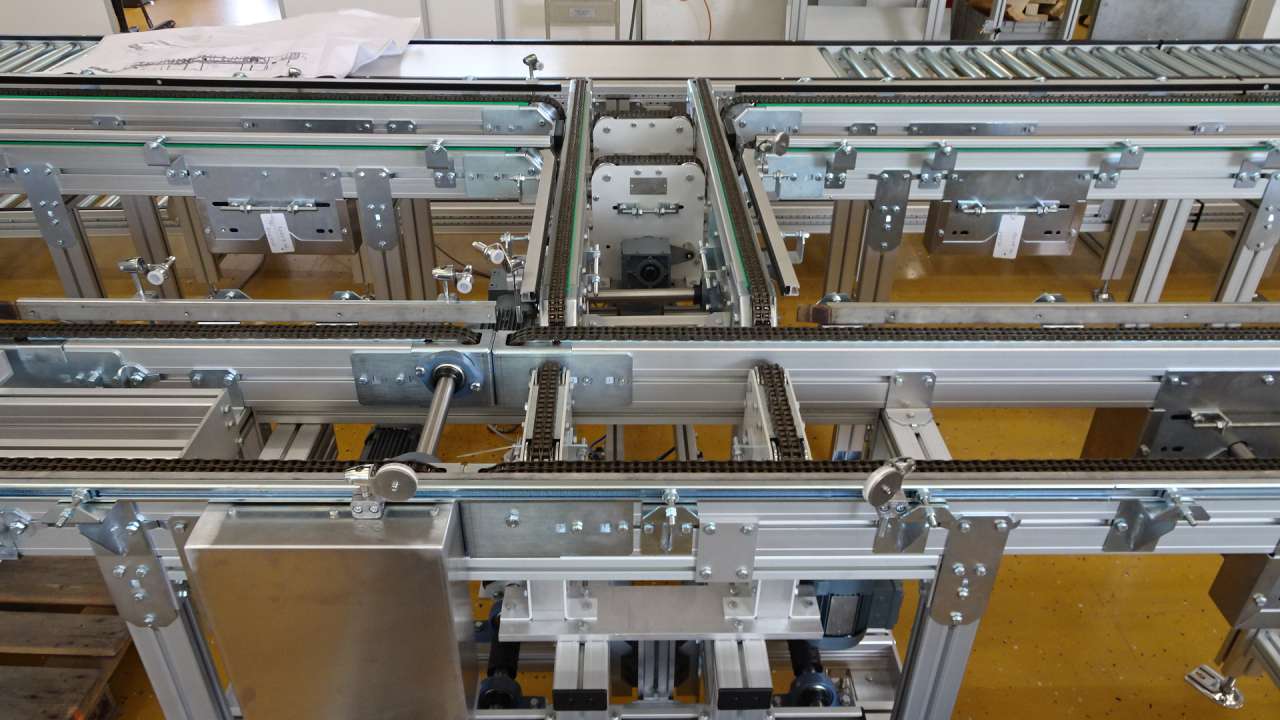

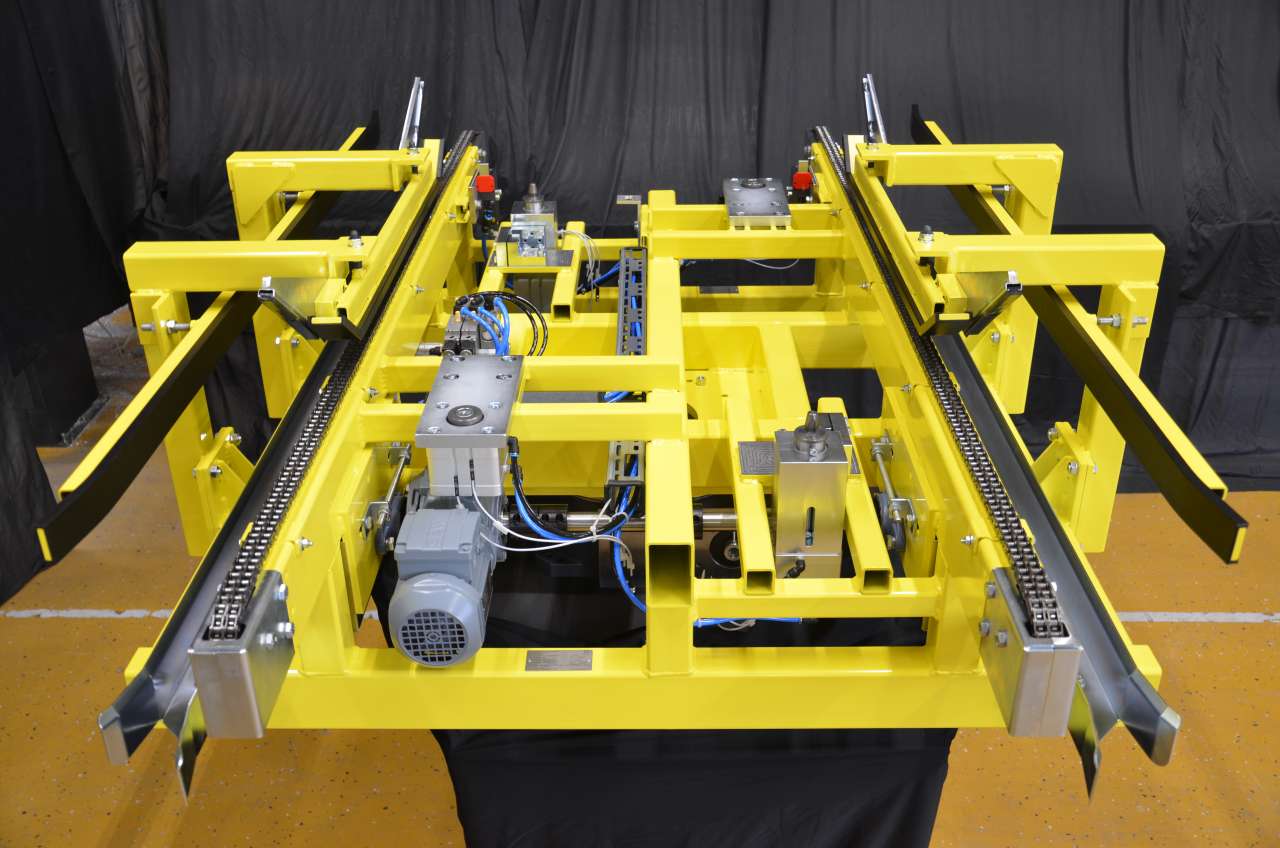

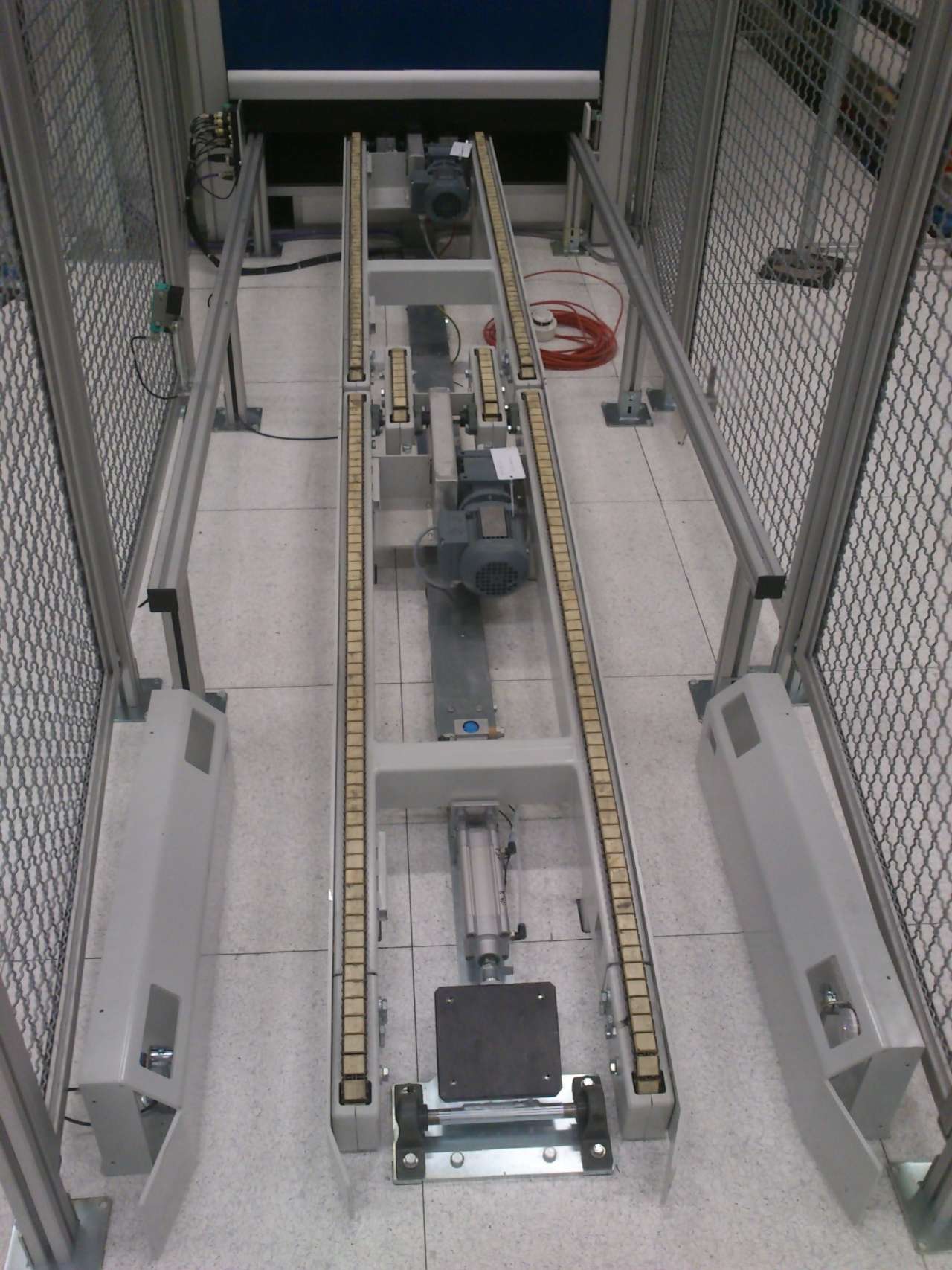

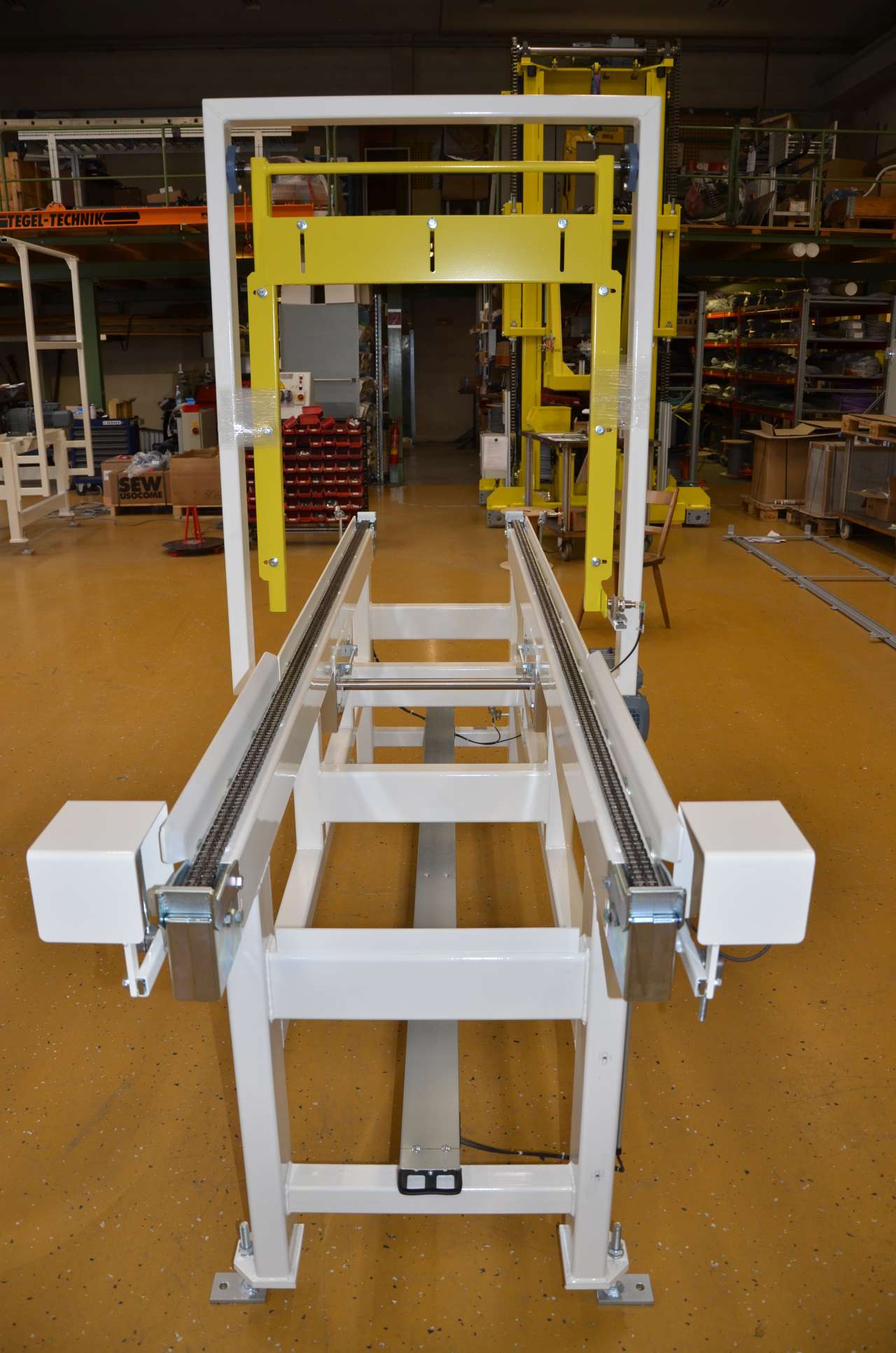

We customise the specific design of the chain conveyors to the requirements and conditions of our customers. This includes the right choice of material, the right chain configuration and equipment with additional functions such as stoppers or turning stations. Depending on the goods to be conveyed, the design varies in two- or multi-strand chain conveyors with roller chains that are adapted to the transported goods. This makes it possible to realise extremely wide conveyor sections, such as those required for the transverse transport of bar goods. An overlap of the strands when using several chain conveyors in a row guarantees a continuous contact surface, which means that even very short goods can be transported.

Multiple chain strands are usually driven by a geared motor and continuous drive shaft. The free space between the conveyor strands allows the transported goods to be accessed from below, which makes it easy to install stoppers or indexing stations on the system.

The dimensions of the chain strands are customised to your conveyed goods or selected and used according to your specific application. In addition to the classic roller chain with straight plates, gentle rubber cleats, claws, angles, prisms or plates are also used for continuous conveyors.

Transport with our powered chain conveyors can be either continuous or intermittent. It is also possible to use the chain conveyors in reversing mode.

Chain conveyors in use

The use of systems with support chains serves, among other things, to reduce downtimes on robot cells. This makes the automation of your processes more efficient and increases the cost-effectiveness of transport, processing or assembly. As a result, the investment in roller conveyors or other conveyor technology solutions pays for itself in a very short time.

Our conveyor technology with chain conveyors is also used by our customers in roller conveyors as corner transfer units to change the conveying direction. One specific application in a robot station is the infeed and outfeed of Euro pallets using roller conveyors. The transverse transfer of the pallets in the station is performed by carrying chain lift transfer units.

Chain conveyors are often used to transport heavy goods. One example of this is the feeding of heavy load carriers with complicated base geometry into a robot station. The carrier chain conveyors transport the goods to the unloading point. The side guides on the chain conveyor simplify insertion and keep the steel frames on the correct track.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0